Shaping the Future of Automation

ABOUT US

At MethG, we innovate and implement best-in-class strategies that suits well and beyond the needs of the client.

To be efficient and make our customers successful, we think beyond the machines in order to deliver the true excellence and achieve customer satisfaction. Our approaches leverage experience, expertise and technology.

WHY WITH US?

We play a vital role in providing automation solutions to our partners and clients.

MethG is a pioneer in industrial automation and applications development that provides world-class solutions to local clientele in the areas of automation system design, assembly and integration services. The thrust areas of the company are design, development, maintenance, system integration and consulting in industrial automation and application system domains.

SOLUTIONS. APPLICATIONS. ENGINEERING.

MethG specializes in offering end-to-end industrial automation solutions for clients across a wide range of verticals in a systematic and professional manner. We assure our clients with a reliable, affordable and long-lasting holistic solution that meets their current and future requirements.

Systems Integration

Engineering Services

Field Services

Maintenance

and the knowledge you would expect from MethG

Training

System Designing & Validation

Following Key Projects were Successfully Completed by MethG

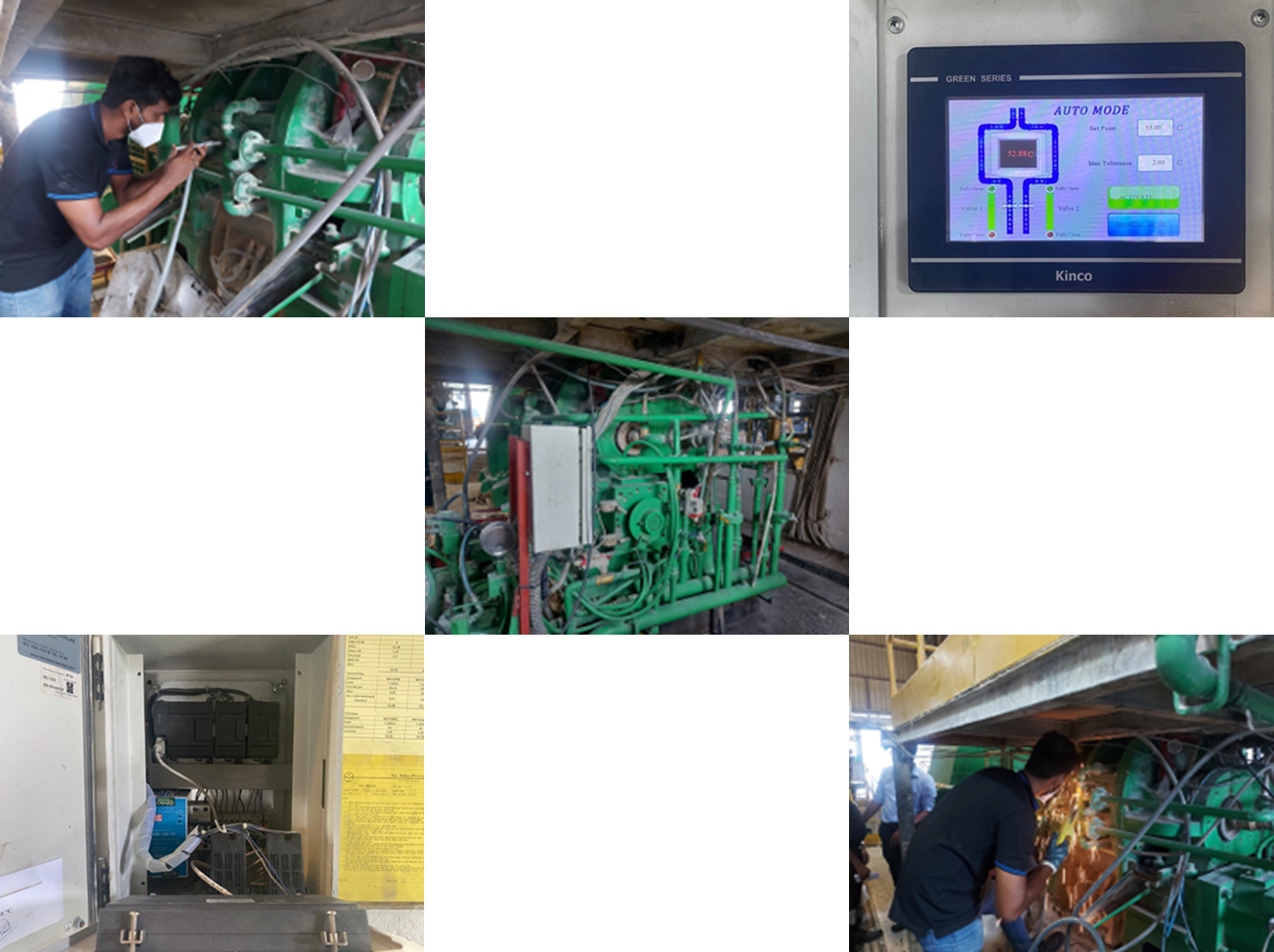

Temperature Control system for the 3D Mixer

The project focuses on implementing a PID temperature control system for regulating the heat generated within a 3D mixer. Utilizing KINCO controllers (PLC), a SELEC PID-500 Temperature Controller, thermocouples, and a Honeywell motorized valve, our system efficiently manages the flow of cooling water through the mixer’s cooling jacket. With real-time temperature monitoring and intuitive control via a KINCO GLO70 HMI, The solution ensures precise and reliable temperature regulation, meeting the customer’s requirements effectively.

SCADA system for Maxmech MCP30 – Batch Processing plant

The project involves implementing a SCADA (Siemens) system for the Maxmech MCP30 Batch Processing Plant. Utilizing components like the CPU-1214C SIEMENS PLC, our system achieves full automation of the concrete mixing process. It generates detailed batch reports, stores them on a server for easy access, and provides consumption reports for resource analysis. This SCADA solution optimizes operations and facilitates data-driven decision-making for improved efficiency.

Concrete Wastage Management System

The project focuses on developing a concrete wastage management system using SIEMENS LOGO! 8 PLC. The system controls the mixing and resting times for concrete wastage in a designated well. It allows users to set specific mixing and resting durations, facilitating efficient utilization of concrete. Additionally, the system enables users to easily adjust the periods as needed, providing flexibility in operation. With Logo 8!, concrete wastage is effectively managed, ensuring optimal usage and minimal waste.

Room Temperature Monitoring System (Test Lab)

The system, integrating the KINCO MK070E HMO-PLC and SIEMENS QFA3171 sensor, guarantees precise temperature control in testing labs. It vigilantly monitors temperature and humidity, promptly alerting users to any deviations from predefined ranges. Temperature data is efficiently stored on a pen drive, facilitating convenient access and detailed analysis, thereby safeguarding the integrity and accuracy of test results

SCADA system for Batch Processing plant

The project involves implementing a SCADA (Wincc) system for the Batch Processing Plant. Utilizing components like the CPU-1214C SIEMENS PLC, our system achieves full automation of the concrete mixing process. It generates detailed batch reports, stores them on a server for easy access, and provides consumption reports for resource analysis. This SCADA solution optimizes operations and facilitates data-driven decision-making for improved efficiency.

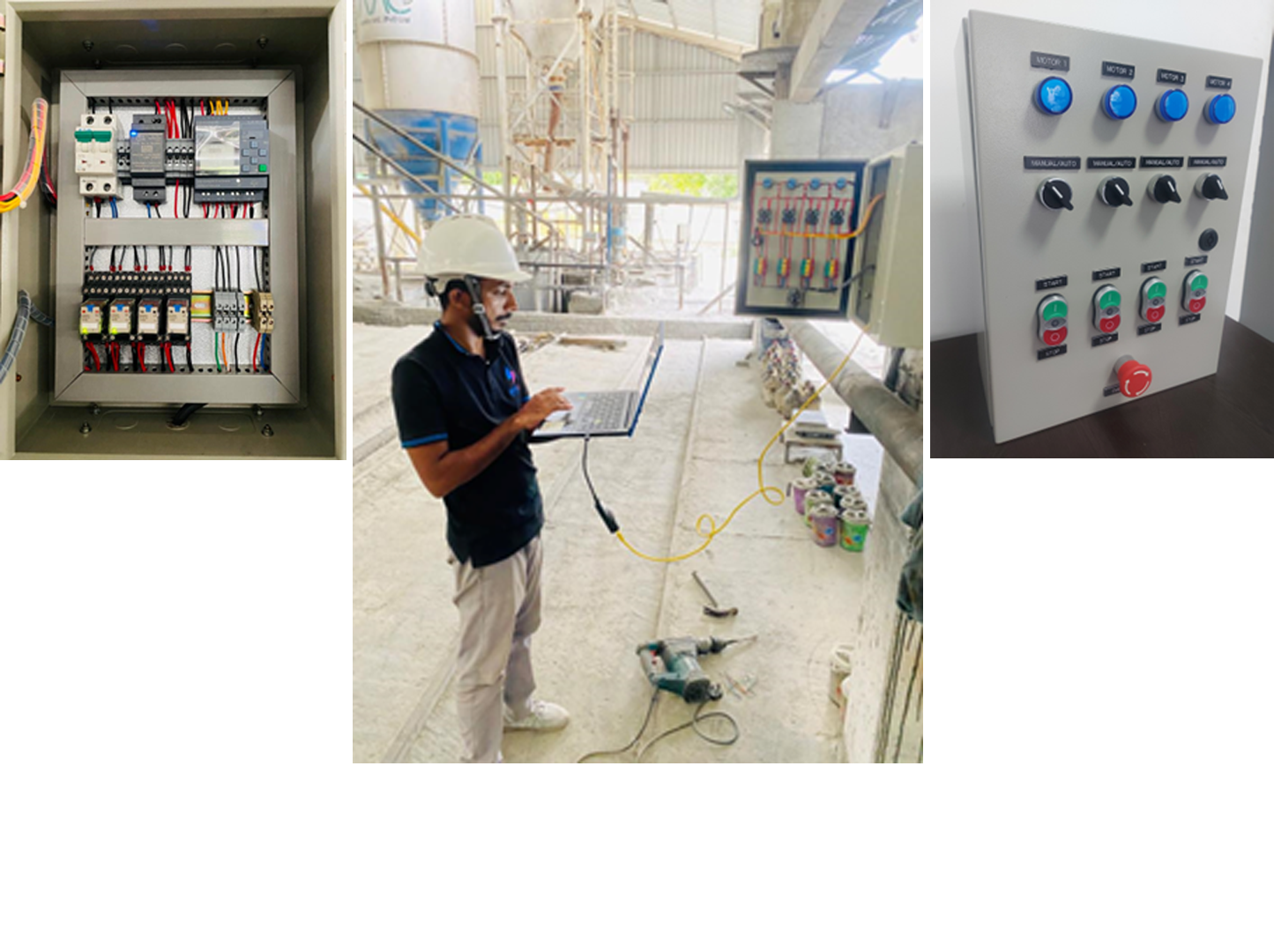

Design, Fabrication and installation of power control panel for swimming pool water circulating system

The project involves designing, fabricating, and installing a power control panel for swimming pool water circulation. It includes essential components such as panel indicators, push buttons, selector switches, and Schneider contactors with overload protection. The goal is to ensure efficient and safe operation, allowing easy control and monitoring of the circulation process for optimal swimming conditions.

Design, Fabrication and installation of Oven Control panel

The project aims to design, fabricate, and install a smaller oven control panel. It integrates key components such as a digital ammeter, temperature controller, panel indicator, push buttons, and selector switch. This compact solution optimizes space while maintaining functionality, providing efficient temperature regulation and intuitive control for enhanced oven operation.

Area Condition Monitoring SCADA System for OSD Facility

The project involves deploying a SCADA (Wincc) system to monitor temperature, humidity, and differential pressure in the OSD facility. Utilizing components like the SIEMENS CPU 1214 DC/DC/DC, CB 1241, and CM 1241, the system ensures real-time monitoring and data storage on a server. It also enables easy report generation for compliance and analysis purposes

High Quality, World Class Brands!

MethG offers a wide variety of automation products that support a full spectrum of industrial applications. From factory automation to process control, our products address a wide range of industrial requirements.

- OMRON

- KINCO

- VEICHI

- Metal Work

- NTA Pneumatic

- Mebra Plastik

- BLIIoT

- SICK

- Pepperl+Fuchs

- Holykell

- Akusense

- WUMA Reducer

OMRON Industrial Automation is a partner to help innovate worldwide manufacturing through its sensing and control technology expertise. They enable manufacturers to operate with greater productivity and streamlined efficiency.

OMRON developed a wide range of electrical products, Sensors, Switches, safety components, Relays, Control Components, Automation Systems, Motion/ Drivers, Robotics, Energy Conservation Support, Environment measurement equipment, Power Suppliers, and so on. Their sales network of approximately 300 offices in 80 countries/territories around the world gives powerful support for our customers’ globalization activities.

Kinco is one of the leading suppliers of manufacturing smart solutions in China. They focus on the development, production and selling of automation standard products and intelligent hardware products. Kinco Automation is one of the leading suppliers with German technology of machine automation and Industrial IOT solution in China.

From 1996, Kinco relied on a full line of automation standard products including Human Machine Interface (HMI), Servo System, Stepper System, Programmable Logic Controller (PLC) and Variable Frequency Drive (VFD), etc. to become the leading brand in China. Kinco has provided complete smart solutions for global industrial automation equipment manufacturer, promoting Chinese automation smart solutions worldwide.

VEICHI is a well-known high-tech enterprise which is professionally engaged in the development, manufacturing and marketing of industrial automation control products. VEICHI Electric (Stock Code: 688698) officially landed in the A-share market and was listed on the Sci-Tech innovation board of Shanghai Stock Exchange on December 29, 2020.

VEICHI has developed a wide range of electrical products, covering variable frequency drives, servo systems, solar pump inverter, PLC, HMI, automation equipment and so on. VEICHI holds the leading position in its main business of inverter manufacturing. VEICHI products are well-known as stable performance, high quality and perfect technical support. They are widely used in many fields such as lifting, machine tools, green energy, motion control, petroleum, chemical, ceramics, metal products, wire and cable, plastic, mining, metallurgy, printing and packaging, textile and chemical fiber, metallurgy, coal, municipal, power and more.

Metal Work is an Italian company specialised in the production of pneumatic components for automation systems. Set up in 1967. Metal Work started out as small workshop manufacturing push-in fittings for compressed air systems. Metal Work currently market five different product ranges: actuators, valves, FRL units, fittings and handling

components.

Metal Work obtained ISO 9001 quality certification in 1992, which was followed by the environmental certification under ISO 14001 in 2000. In order to guarantee an occupational health and safety management system, in 2007 Metal Work applied to them the British standard OHSAS 18001, and then moved on to ISO 45001 in 2019.

NTA Pneumatic is aimed at manufacturing good quality with innovative ideas and will take out 5% turnover for R& D to adapt to the market trends. As far as quality control is concerned, NTA provides regular management training programs for employees to improve their awareness of proper quality control system, meanwhile enhance their operation effectiveness. From raw material to finally packaging, there are more than 30 processes.

More than 10 years of experience in the industrial automation field, perfect management systems, healthy financial support, great produce and sales team… all of these points support NTA more and more popular in the pneumatic line.

Mebra Plastik represents now a well-established worldwide reality in the field of extrusion of tubes for hydraulic and pneumatic. Production of polyamide, polyurethane, multi-layer, polyethylene and flouropolymer hoses for hydraulic and pneumatics.

Our processes are certified ISO 9001 and our products are made from a selection of the best raw materials on the market. The high-level quality standards always pursued by our company allow us to obtain products with specific technical requirements and extremely tight tolerances.

King Pigeon Communication Co.,Ltd. found in 2005. Specialized in Cellular M2M RTU, Cellular IoT Gateway, LoRa Gateway, Industrial Remote IO Modules manufacturing, and IoT Cloud Platform development, Provides One Step Complete IoT Solutions. Since its inception, King Pigeon has been dedicated to the improvement of IoT solution technology and the development of new and innovative IoT solutions to address the increasingly rigorous demands placed worldwide. So far, more than 220 IoT Devices are available, sold more than 1,000,000 IoT Devices to 200 countries and regions, and the growing trend still keeps at high speed. King Pigeon confident that with our R&D, quality, and service, they can supply more and more industrial IoT solutions to satisfy our customers.

Sick AG, based in Waldkirch, Germany, is a global manufacturer of sensors and sensor solutions for industrial applications. The company is active in the areas of factory and logistics automation and process automation.

Analyzer solutions, Array sensors, Automation light grids, Color sensors, Contrast sensors, Capacitive and magnetic proximity sensors, Detection and ranging solutions, Distance sensors, Dust Measuring Devices, Fiber-optic sensors, and fibers, Flow measurement technology, Fork sensors, Gas Analyzers, Glare sensors, Identification solutions, Inductive proximity sensors, Ect.

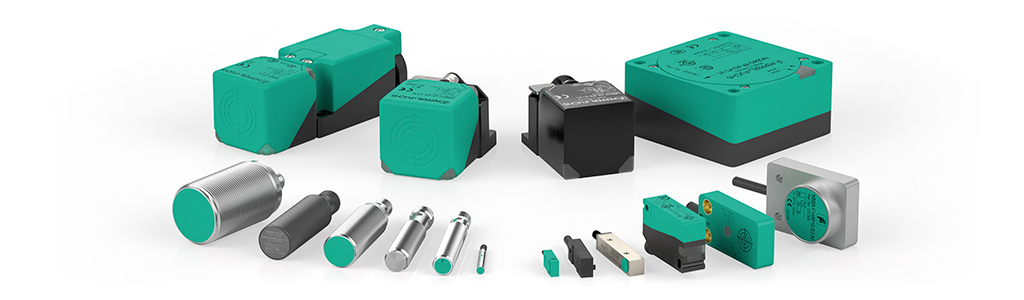

Pepperl+Fuchs SE is a German multinational company with its headquarters in Mannheim, Germany. The company manufactures products for fabrication and process automation and is specialized in sensor manufacturing.

Proximity Sensors, Photoelectric Sensors, Industrial Vision, Ultrasonic Sensors, Rotary Encoders, Positioning Systems, Inclination and Acceleration Sensors, Industrial Communication, Identification Systems, Displays and Signal Processing, Connectivity, Accessories, Software

HOLYKELL was established in 2001. They have been focusing on the R&D and sales of various measuring instruments such as submersible level sensors, ultrasonic level sensors, smart wireless solutions, electronic pressure switches, air differential pressure sensors for many years.

More than 80% of HOLYKELL employees have bachelor’s degree. At present, HOLYKELL has more than 120,000 customers worldwide and it’s products are exported to 175 countries in Europe, America, Australia, Africa, SouthEast and Asia.

Akusense is a manufacturer of precision and intelligent sensor solutions and product design, and a national high-tech enterprise. The company has more than 120 core patents and more than 20 invention patents. Since its establishment, Akusense’s annual product iteration speed has led domestic counterparts.

Among them, background suppression photoelectric sensors, reflective photoelectric sensors, ultra-thin photoelectric sensors, laser scanners, sensor test boxes and other products have been favored by users in Europe and the United States. Every year we install more than 2.000.000 in total around the world. Many of the world stop manufacturers, suppliers and integrators use our products to ensure that the products they produce meet the quality requirements of users.

Zhejiang Wuma Reducer Co. Ltd is a national Hi-tech enterprise who pecialized in developing and production of various types of speed reducers.

Their main products are RV series worm reducer, helical gearbox, WAH series hypoid gear reducer, precision planetary gearbox etc., more than ten series of products. They can also provide the service with special and customized products. Our products have been widely sold to all over China and exported to other countries and regions like Europe, America, Hong Kong, Taiwan and Southeast Asia, and so on.

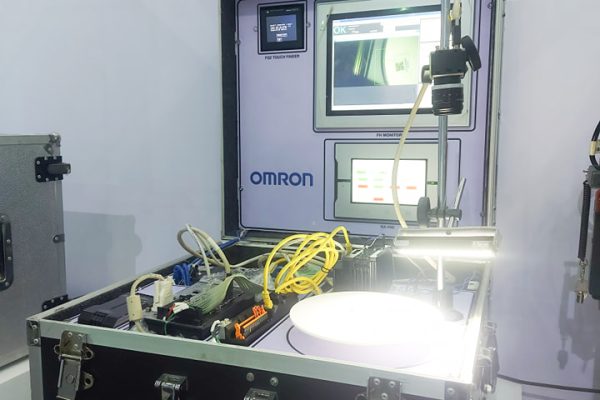

We are honored to be one of the sponsors of the prestigious Techno 2023 exhibition. A big thank you to Techno Sri Lanka for organizing such an impactful event.

Special appreciation to Omron Industrial Automation India and our esteemed partners – VEICHI Electric Co., Ltd., Kinco Automation, WECON Technology Co., Ltd., Zhejiang Wuma Reducer Co.,ltd, Holykell Technology Company Limited, and others for their invaluable support with products and expertise.

Kudos to our dedicated MethG team whose hard work contributed significantly to the success of this event.